Define Success Before You Compare Software

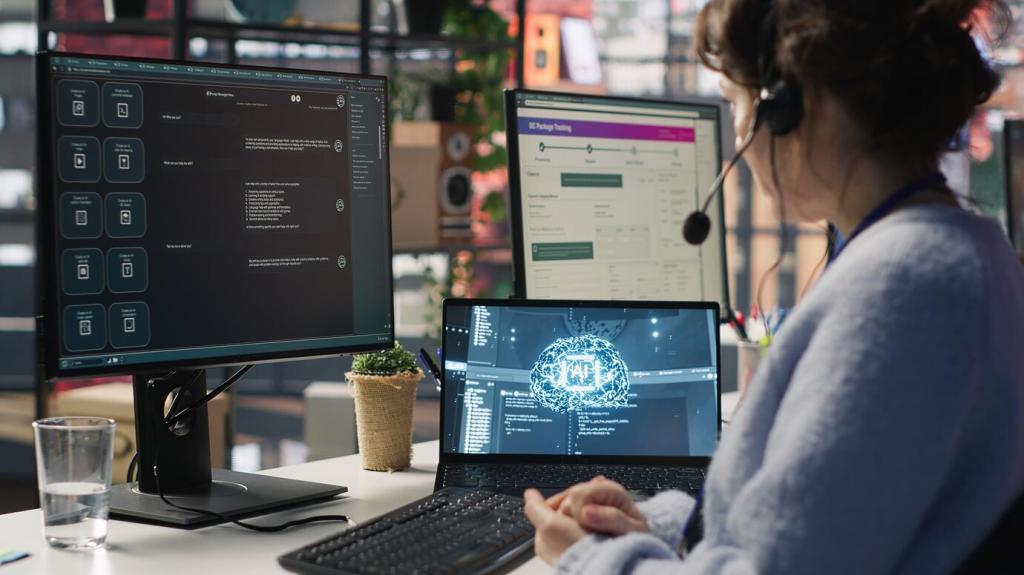

Write goals like fewer stockouts, faster picking, cleaner close, and fewer manual touches. If a feature cannot move a specific metric, question its priority. Share your top three goals in the comments to keep yourself accountable.

Define Success Before You Compare Software

Decide acceptable budget ranges, target go‑live windows, and any regulatory needs like lot traceability or 21 CFR Part 11. Add practical realities: Wi‑Fi coverage, device types, and seasonal peaks. What constraints worry you most? Tell us.

Define Success Before You Compare Software

Include receiving, picking, finance, and IT. Listen to the person who scans totes at 3 a.m.; their friction becomes your rework later. Invite those voices to demos, and subscribe for a stakeholder checklist you can copy today.

Define Success Before You Compare Software

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.